Machin-learning-based focus detection for laser micromachining

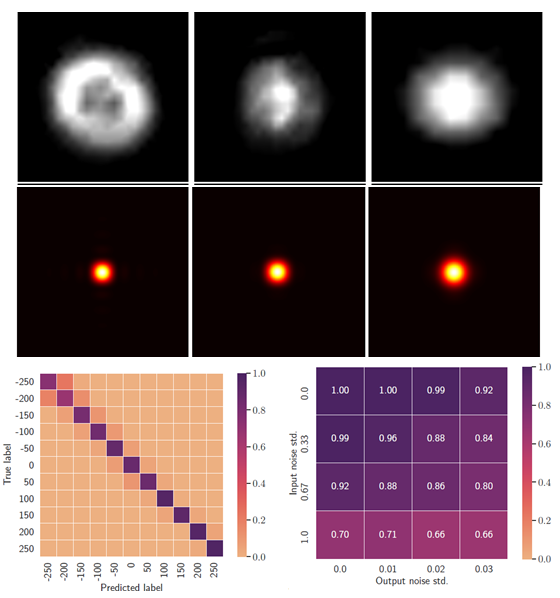

In high-precision laser material processing, finding the exact focus position of the material is crucial. We explore a real-time and high-precision focus finding for ultrafast laser material processing and micromachining. We use a convolutional neural network (CNN) approach to train and detect the focus position. We also investigate the effect of the surface roughness and the optical noise (from the camera, for instance) on the precision of detection.

Our research is based on experiments and simulations.

Intracavity optical tweezers

Optical tweezers are a powerful technique to manipulate microscopic and nanoscopic particles and living cells. We enhanced the optical tweezers' action by taking advantage of intracavity nonlinear feedback forces emerging when the microparticle is placed within the laser cavity. (intracavity OT). Thanks to power self-regulation, due to optomechanical coupling, the average intensity on the particle reduces, significantly. We work on single beam and counter-propagating OT (BAP, Start-Up, 2022-2023).

We are interested in both experiments and theory.

Fiber laser development for food science and food technology

Lasers have extensive applications in food science and food engineering. Food processing, detecting, and packing are some of the main topics in this area. Laser-induced breakdown spectroscopy (LIBS) has become a rapidly rising trend in studying structural and compositional aspects of food analysis due to its numerous advantages, such as minimum or no sample preparation, the ability to analyze liquids, gases, and solids with multi-elemental analysis. We aim to develop a new generation of laser-induced breakdown spectroscopy for food science based on ultra-high repetition rate fiber lasers (TUBITAK 1001-2022-2024).

Surface and subsurface material processing and imaging

Ultrafast fiber lasers are widely used in industry and medicine for micro and nano-processing of materials and tissue. We aim to develop a high-power, ultra-high repetition rate Er-doped fiber laser for surface and subsurface material processing, especially silicon. The laser material processing will be integrated with digital holography microscopy (DHM) for real-time imaging and characterizing (YÖK, Research University Support Program, 2022-2024).